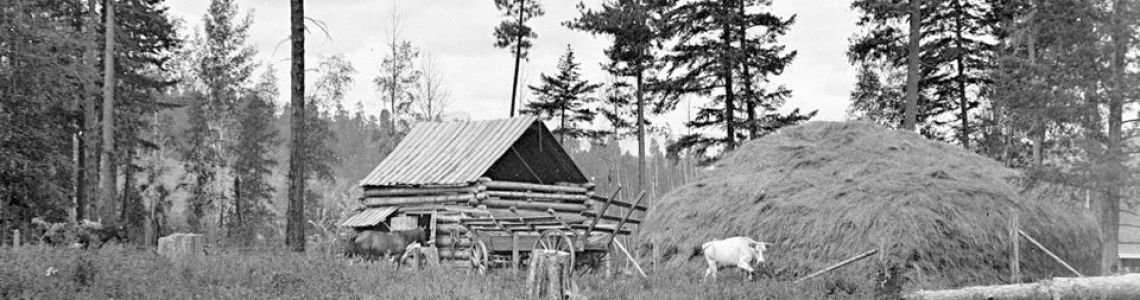

Following upon previous blogs on logging in the region in the 1920s, I have more recent and personal remembrances to relate. My father, Harold, and grandfather, Harry, operated a portable bush mill on the Commonage in the 1950s, supported by horse logging. The operation was located off Commonage Road opposite Tompson Lake. In fact, the little cabin that they used as a horse barn and for storage of equipment still appears visible on the left as one turns up Howards Road. The mill produced small dimension lumber and ties that they had contracted to sell to the CNR.

One recent and related incident is that my late mother received a letter from a lawyer asking her to sign off on a document dating from that era. My grandfather had signed an agreement with the landowner allowing him to cut timber on his land and that contract had no termination date. The property development could not go ahead without agreement from descendants of every branch of grandfather’s family to close the contract. Mom relinquished the right to log the area, without compensation I must say. She said that she never was much good with a chainsaw.

The mill was built by Harry at the Thomson Garage shop in Oyama. It was operated by my uncle, Ira Thomson, who was a qualified machinist and welder. The mill was built on a truck chassis with the wheels retained, such that the mill could be pulled to a new location by our D2 Caterpillar tractor. Harry also built his own forklift, using a 1937 GM truck chassis, motor and drive train, by turning the steering mechanism around so that the motor was at the operator’s back. I recall that the forklift was frequently in the garage for maintenance, likely because the steering mechanism was awkward with the steering wheel facing away from the turning wheels. The Thomson Garage was the centre of mechanical operations for the mill operation. Upon opening up one morning, my father pushed up the large overhead door too vigorously and the door sailed off its track, falling onto his head. On another occasion, he came home quite badly hurt because the head saw had “thrown a slab,” that projectile catching him in the upper arm. Industrial accidents were quite common in that era, at least at this operation.

The total logging and sawmill operation usually employed five men, including Harold and Harry. Dan Joe and his son, Raymond, of the Splats’in First Nation near Enderby were employed as teamsters. My father was the faller although they might have employed a second faller because he also assisted in operating the mill. A lot of varied activities were required at the mill site, canting the log to the mill carriage, securing the log on the carriage and flipping it repeatedly to saw slabs from each side, piling lumber and ties for later transport, removing slabs and sawdust from the immediate area, looking after the horses, etc.

I recall one evening accompanying my father to the railway siding in Oyama to load a boxcar with ties from his three-ton Fargo truck. I was a young teen and perhaps of limited assistance, but I remember that it was exhausting work. Each heavy, green-timber tie had to be manually removed from the deck of the truck and loaded into a boxcar. Those of you who have been in a railway boxcar will appreciate the effort required to pile ties at the far ends of the car.

Because the mill could be moved to a new location relatively easily, the skid trails were only one half to one km in length. The logging horses were amazing. They obeyed verbal signals, Gee, Haw and Whoa, but in some circumstances these horses operated without signals of any kind. “Sandy” was one of my father’s well-trained and intelligent logging horses. The faller in the woods would cut the logs into lengths and de-limb them and then a teamster would hook a single log to Sandy and send him on his way along a skid trail. Sandy would travel along unaccompanied, carefully staying on the topside of the skid trail, until he arrived at the mill. If he hit a snag along the way, he would not strain himself, but would wait for help. Sandy would stop at exactly the spot where a man, using a cant hook, could roll the log toward the mill. This small operation didn’t maintain a log yard, rather they milled the logs as they were delivered, generally with only a few in inventory.

I regret having no photographs of the mill or the horses.

By: Dr. Duane Thomson

Lonnie Dalzell

My Grandfather is Harry. I always thought I got my love of chainsaws and tree felling from my dad but apparently it was also through my mother’s blood line.

Uncle Duane, I love the research and love learning about my family and the important role they played in the Okanagan!

Lonnie Dalzell

Sorry Harry was my Great Grandfather.